Responsive Menu

Add more content here...

Customization instructions: All specifications are customized according to the actual situation of the customer, and non-standard customization is supported.

| Material quality | PVDF+C carbon fiber reinforced composite material |

|---|---|

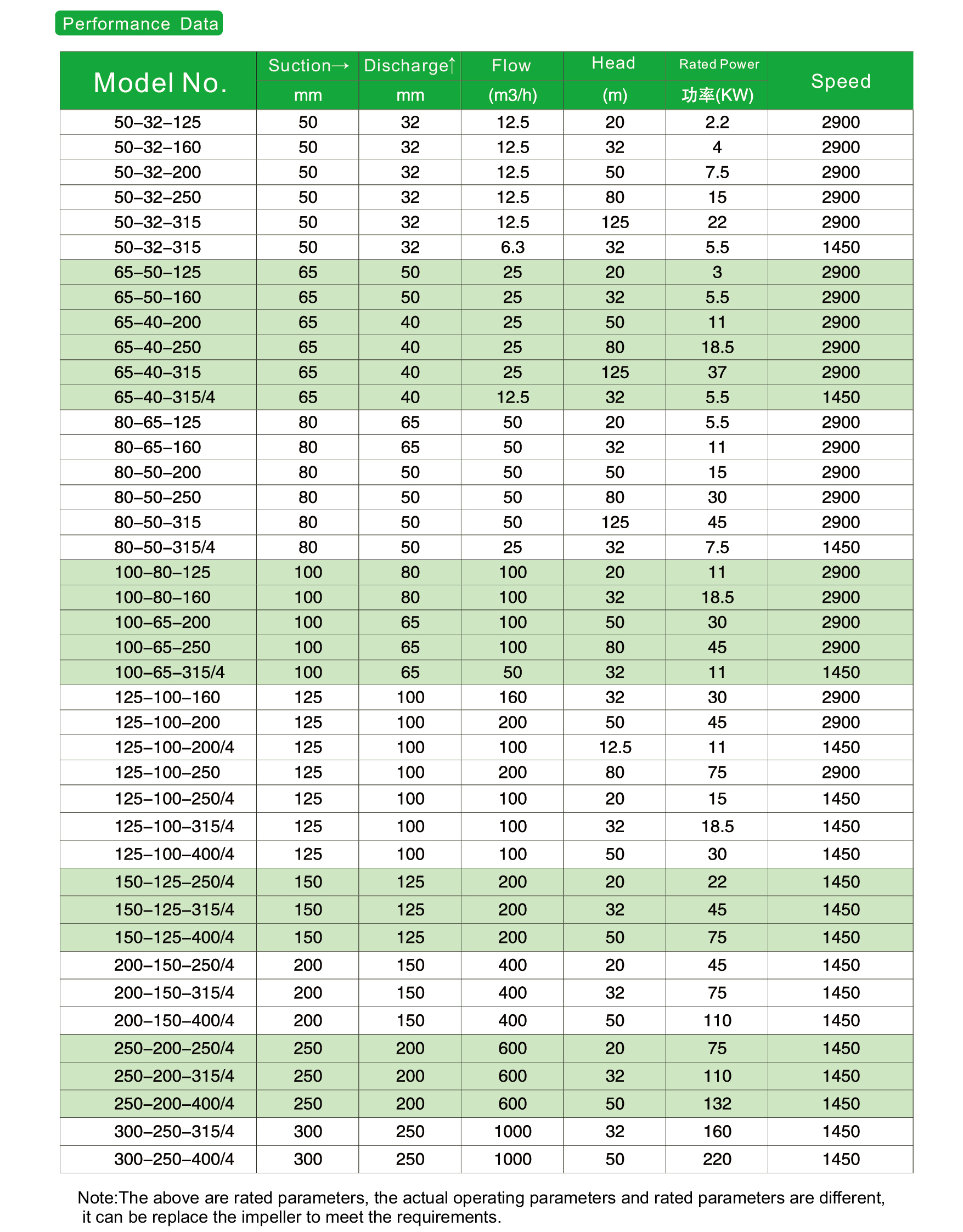

| Performance parameter | Flow:12.5-1000m³/h Head:12.5-125m |

| Power | 2.2-220kw |

| Applicable media | sulphuric acid/alkali |

Inventory delivery: LC heavy-duty self balancing metal magnetic pump is in stock, with nationwide delivery guarantee!

Special note: The product images and parameters may differ slightly from the actual product.

PRODUCT DESCRIPTION

JFK engineering plastic splint pump is a high-end corrosion and wear resistant centrifugal pump carefully built by R & D team for years. The pump adopts the latest international hydraulic model, the CFD calculation method, combined with relevant standards to design, its performance and size equivalent in line with ISO2858 standards, can be customized according to user requirements API610 standards.

Pump body part adopts splint structure design, equipped with front cover and back cover, impeller is semi-open structure, pump body material standard with 6 million ultra high molecular polyethylene, can be equipped with high imported PVDF+C carbon fiber reinforced composite material, thickened design, the minimum design thickness is 30mm, strong wear resistance, the standard is patent double end mounted static mechanical seal. It can be widely used in “strong corrosion, strong abrasion, high temperature” conditions, as well as corrosive slurry conveying with easy crystallization and high solid content.

Design Character

Main Application

The pump design is positioned with high-end wear resistant pump, so it can be widely used in phosphate fertilizer, non-ferrous smelting, desulfurization and denitrification, lithium iron phosphate, iron and steel pickling, filter press feed and other industries or stations.

Standard material (UHMW-PE) Applicable temperature :-20C-80℃. High material (PVDF+C) applicable temperature:-40℃-140℃

PRODUCT PARAMETERS

PRODUCT STRUCTURE DIAGRAM

==

If you are interested in our Pump industry products, want to know more details and get offer from us, please leave a message here, we will reply you within 12 hours.